How Calyx Packaging Keeps a Lid On Waste

Here at Calyx, we work hard to reduce our emissions from energy use, because having a sustainable product is our top priority. Our manufacturing process reduces wasted time, energy, and materials by utilizing bi-injection molding and hot runner systems. Learn how Calyx packaging is mindfully manufactured to reduce our production’s environmental strain on our planet.

Stay in touch!

Join our email list to receive Calyx content & product updates.

By Calyx Containers in Sustainability at Calyx , Cannabis Packaging

According to the EPA, the three primary sources of greenhouse gas emissions in the US are transportation, electricity, and industry. The impact of energy use in industry alone accounts for about a quarter of the world’s total emissions. Here at Calyx, we work hard to reduce our emissions from energy use, because having a sustainable product is our top priority. Our manufacturing process reduces wasted time, energy, and materials by utilizing bi-injection molding and hot runner systems.

Read on to learn how Calyx packaging is mindfully manufactured to reduce our production’s environmental strain on our planet.

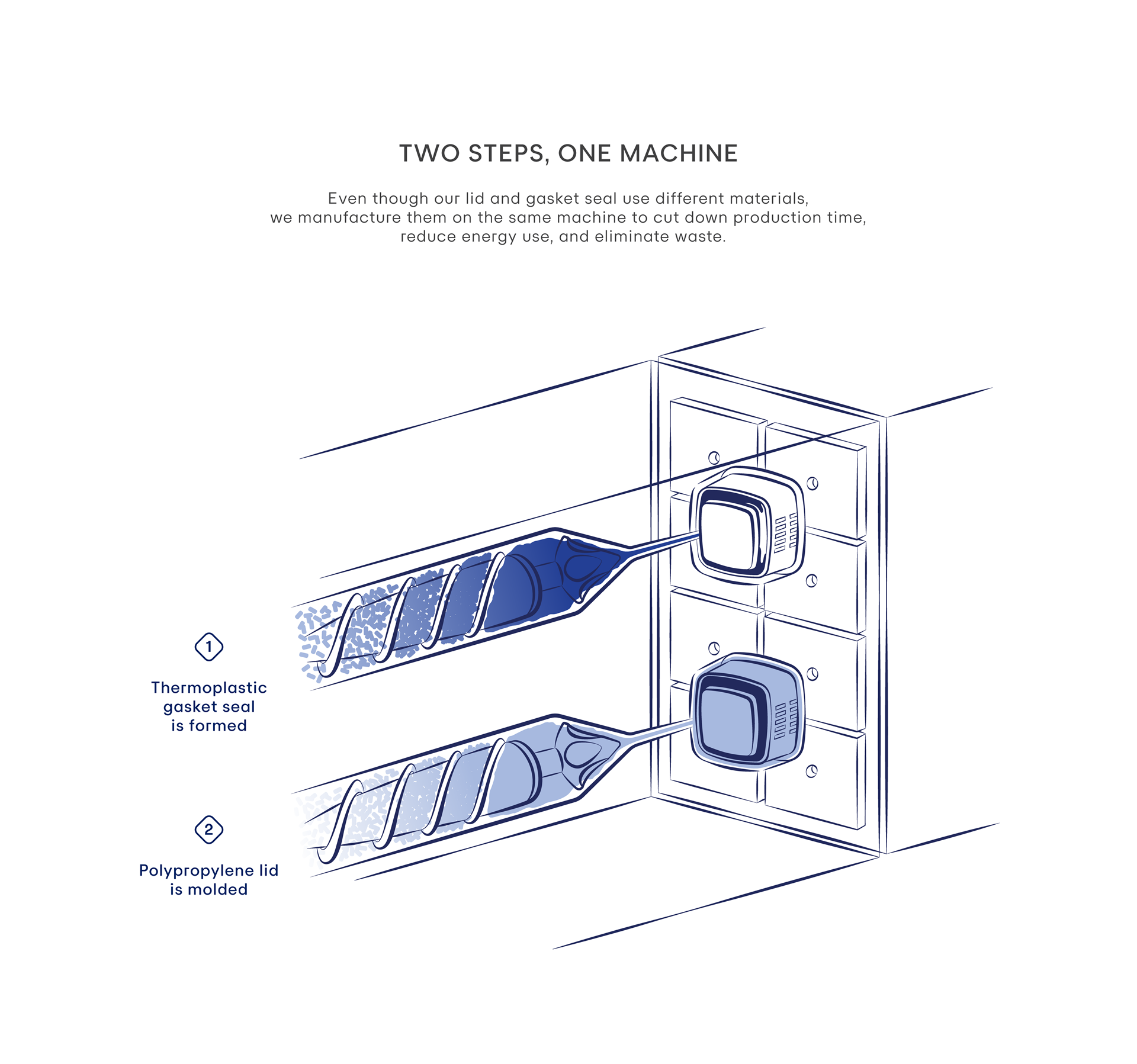

What is Bi-Injection Molding?

So, how does bi-injection molding work? At a high level, it’s when two materials with different properties are injected into the same mold—hence the “bi” in bi-injection. Calyx uses this process to manufacture our lid and gasket seal directly in the same mold. With this technology, our lids provide a sustainable seal that keeps cannabis products fresh.

Our thermoplastic gasket seal is molded first. Then, polypropylene is injected into the mold around the gasket seal to create the rigid square lid that our customers know and love.

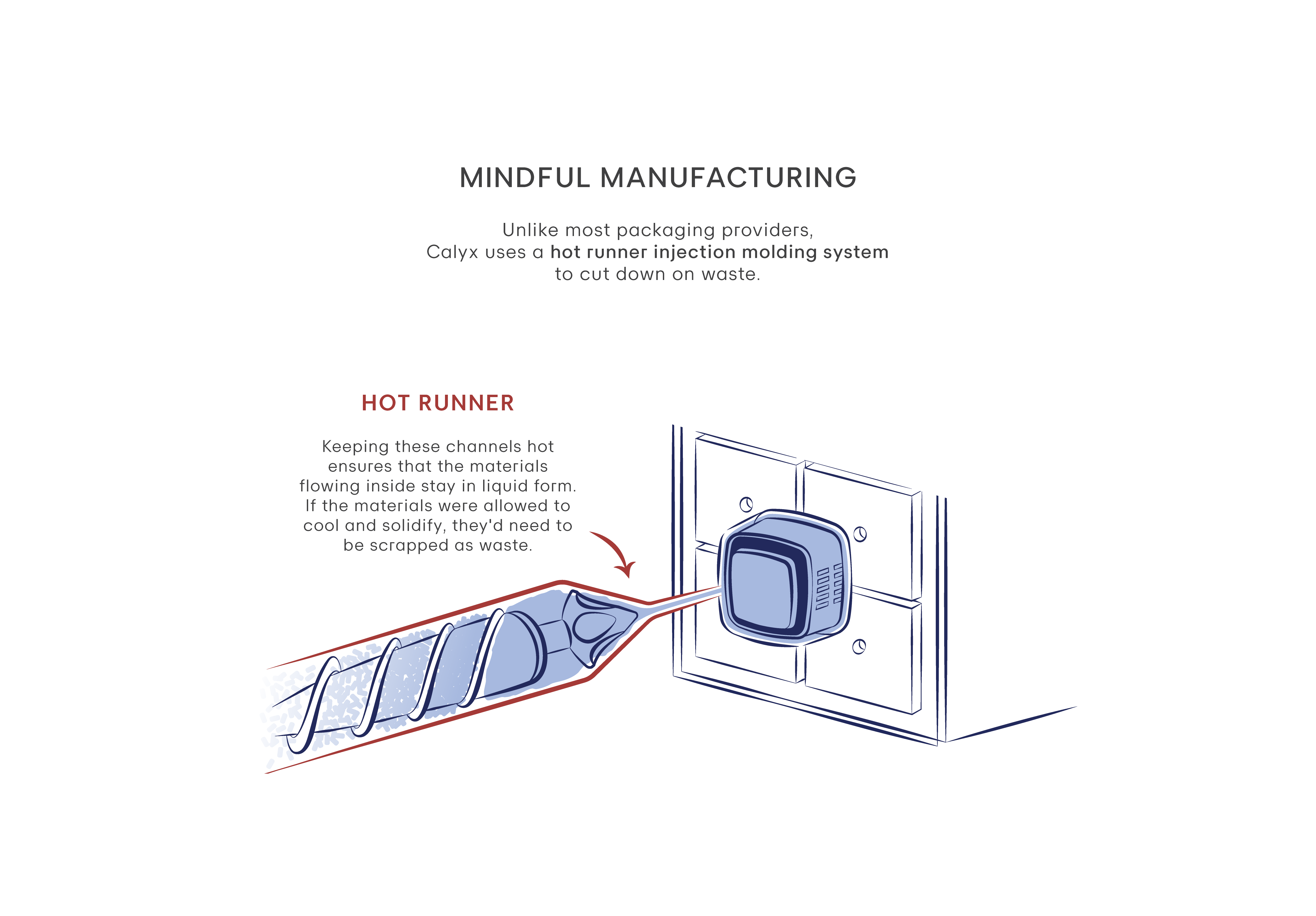

We Run Hot

Within the bi-injection molding process, runners deliver hot material to part cavities and form the final product. There are two types of runner systems, hot and cold, although material always needs to be heated before being injected into part cavities. This makes cold runner systems the less efficient option since they require heating, cooling, scrapping or reprocessing cooled material, and heating material all over again.

Other packaging providers commonly use cold runners. In this case, molten plastic is injected into the part cavities through runners–just like in hot runner systems. However, since the plastic in the runners is then allowed to cool and solidify, it must be cut off from the newly molded part. Ideally, it’s recycled and reprocessed.

Using this cold runner system results in longer cycle times for cooling and requires manual labor for runner handling, maintenance, trimming, and regrinding of the material.

We keep our runners hot. This ensures that none of the plastic flowing through the runners is allowed to cool and to be scrapped as waste. Since Calyx uses hot runners, our molding process uses less time and energy than cold runner systems and produces zero waste.

How Does Bi-Injection Molding Stack Up to the Competition?

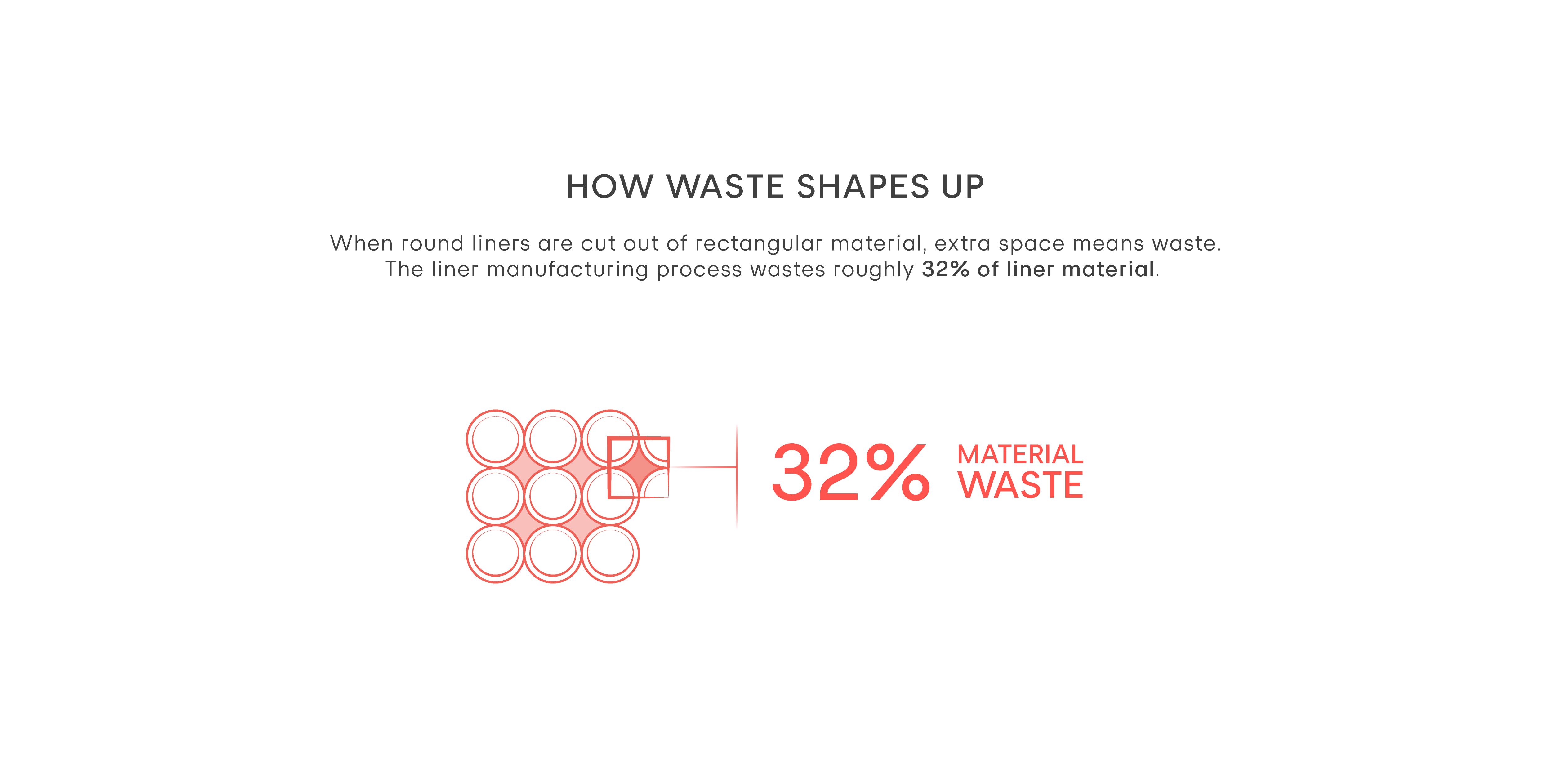

Lid liners used on standard round packaging aren’t produced via bi-injection molding, and their inefficient production methods result in excess material waste. These round liners are produced separately from the lid by cutting round shapes out of rectangular sheets of material. All that space between the circular cuts of liner is waste!

These liners are glued to their lids to assemble the final part, adding yet another step to the manufacturing process. Not to mention the use of adhesives to bond two different materials together creates a potential contaminant in the eventual recycling stream. If the lid itself is recyclable, this puts the responsibility on the consumer to remove the non-recyclable seals prior to recycling.

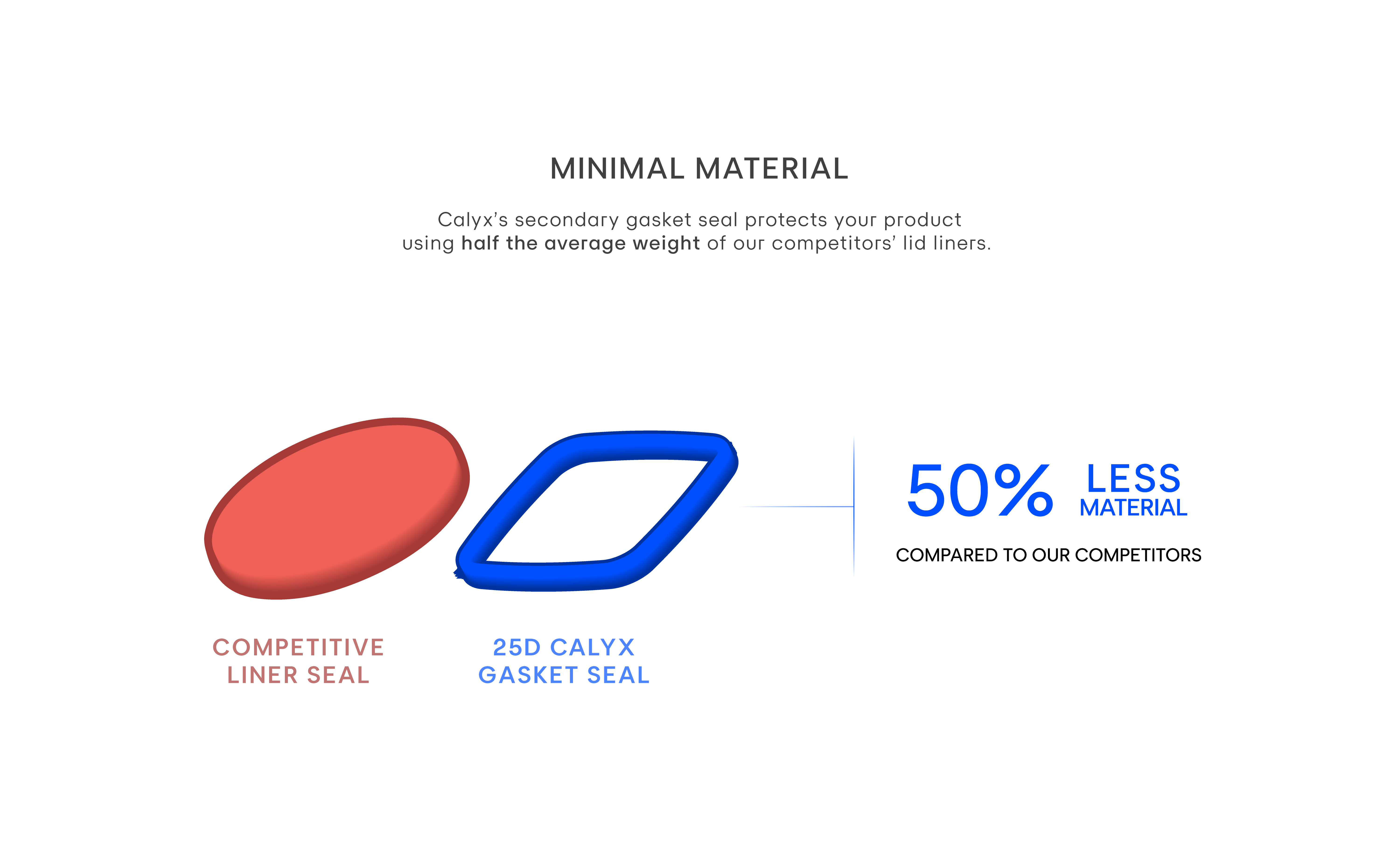

Calyx lids are thoughtfully manufactured to cut down on processing steps, material waste, and harmful adhesives. Bi-injection molding allows our seal to consist of significantly less material than other packaging options, with the average weight of a competitor liner being twice as much as our standard 25 Dram gasket seal.

Compared to the process used to manufacture standard lids and liner seals, bi-injection molding:

- Requires less material

- Reduces production time

- Uses less energy

- Produces zero material waste

Calyx lids are also made of polypropylene, which is #5 plastic–one of the most high value materials for recycling. The thermoplastic gasket seal is safe for recycling with polypropylene, so these lids don’t require any disassembly prior to responsible disposal.

Check out this guide for more information on how to recycle Calyx packaging.

Choosing Calyx for your packaging needs is the more sustainable option, and your customers will definitely thank you for it.

Even More Benefits

In case you needed some more reasons as to why Calyx cannabis packaging is a sustainable, innovative option, here are some additional benefits.

Reusable Containers

Thanks to our gasket technology, our lids allow consumers to reseal after every opening.* We lock out moisture, light, and oxygen to keep your cannabis fresher, longer. Plus, our drams and glass jars are food-grade and dishwasher safe, so consumers can continue to use them long after the cannabis product is gone.

Ready to Ship from the USA

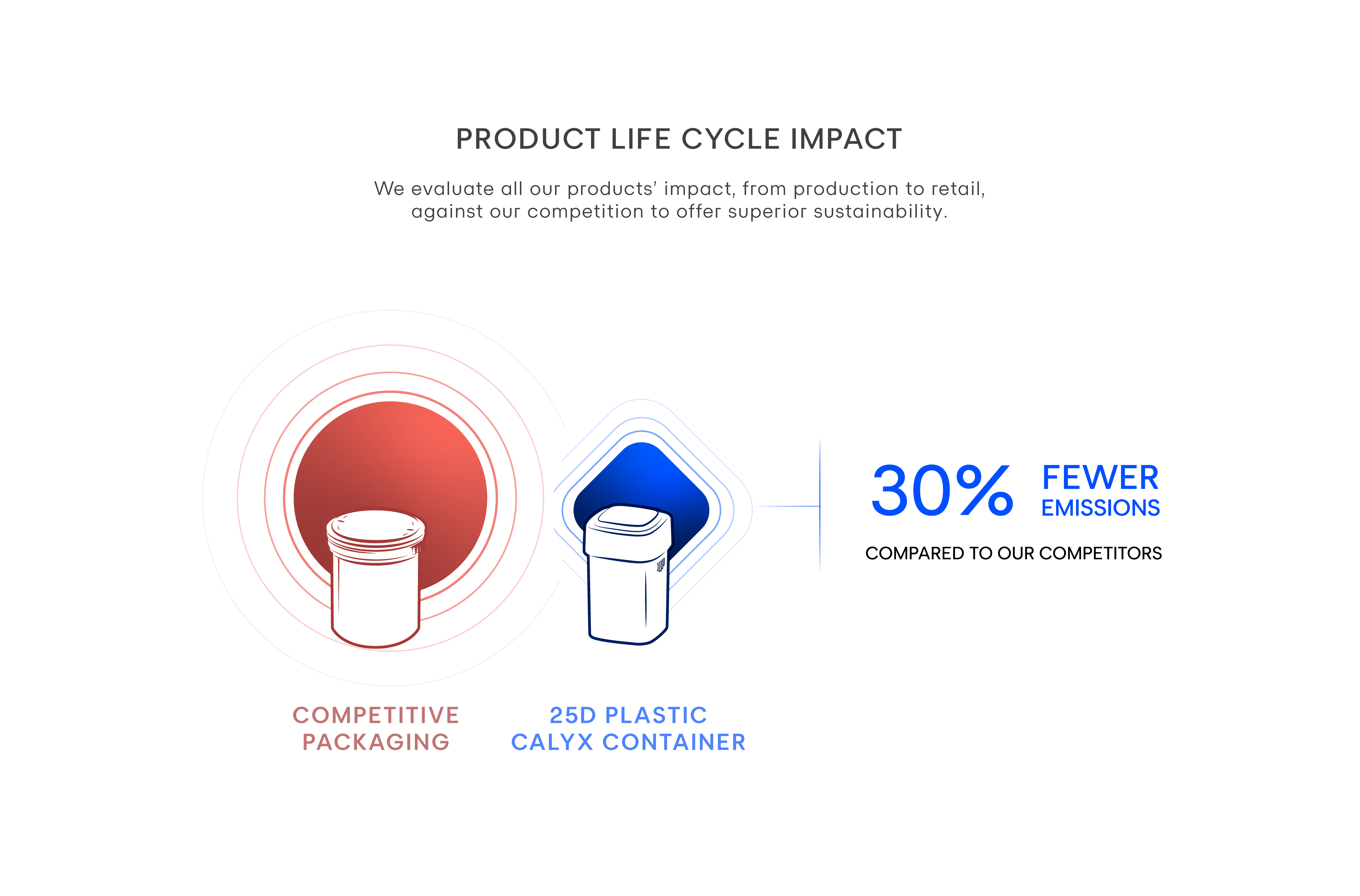

Our popular 25 Dram container produces 30% fewer emissions than other cannabis packaging due to its mindful manufacturing, compact square shape, and US-Based inventory, fulfillment, and manufacturing. Sourcing overseas exhausts energy and transportation emissions, and sourcing closer to home ultimately reduces strain on the planet.

Calyx + Sustainability

Our unique packaging is designed to lighten our (and your!) impact on the environment. Through efficient manufacturing processes, we’re able to keep a lid on waste while keeping your cannabis product fresh. We know manufacturing processes aren’t the “hottest” of topics, but we think it’s a critical area of focus when designing for sustainability.